Contact us

Our team would love to hear from you.

The logistics sector is beset with daily challenges, ranging from high transportation costs and fuel price volatility to the limited visibility of shipments and delivery delays. With the advancement of groundbreaking technologies like AI, are logistics businesses ready to overcome obstacles and elevate their operations to a whole new level?

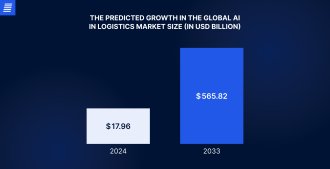

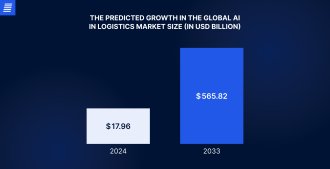

Precedence Research projects that the global AI in logistics market will skyrocket from $17.96 billion in 2024 to $565.82 billion by 2033. In this article, we focus our lens on AI in logistics, highlighting relevant use cases, benefits, challenges, and successful examples of AI implementation by industry leaders. We also offer practical guidance on how to effectively integrate this new technology into your logistics and supply chain operations, helping your business thrive in the digital transformation era.

Logistics has always involved complex workflows and multifaceted processes, requiring comprehensive planning and the coordination of numerous stakeholders to ensure the uninterrupted flow of goods and services across the supply chain. Moreover, the industry is constantly affected by economic, political, social, and environmental factors, including gross domestic product (GDP), national policies and regulations, evolving customer demands, climate change, pandemics, and more. AI allows logistics companies to predict the impact of these factors on the industry and adjust their processes accordingly. What, though, is AI in logistics all about?

AI in logistics focuses on using machine learning (ML), deep learning (DL), computer vision (CV), natural language processing (NLP), and predictive analytics to automate and optimize tasks of varying complexity across logistics and supply chain processes. By analyzing vast amounts of relevant data, AI provides valuable insights into logistics operations and existing bottlenecks, predicts possible outcomes, supports data-driven decision-making, and enables more efficient, accurate, and strategic logistics processes. Companies that incorporate AI into their supply chains can reduce operational expenses, maximize performance and productivity, increase customer satisfaction, and achieve other key benefits. For instance, McKinsey reports that early adopters of AI in supply chain management have enjoyed 15% lower logistics costs and significant improvements in inventory management (35%) and service levels (65%) compared to companies slower to embrace AI. Given the current transformative impact of AI, we can expect it to continue expanding, significantly impacting key logistics aspects like inventory management, warehousing, order processing, distribution, and transportation.

Autonomous cars rushing to make last-mile deliveries, drones navigating the shortest possible routes for delivering medical supplies, and human-like robots shuttling goods in warehouses—these are just a few examples of how AI is transforming the logistics sector. Are you curious to learn more? Read on as we explore AI logistics use cases.

An efficient inventory management process ensures that the right products are available at the right time, and the use of AI in logistics makes this possible. Through predictive analytics and ML, businesses ensure real-time visibility across the entire supply chain, gaining an accurate view of available inventory and optimizing stock levels based on current demand. With intelligent inventory management, logistics companies can expedite the fulfillment of customer orders and the delivery process, minimize the risks of overstocking and understocking, reduce material waste, and achieve other significant improvements.

Developed from scratch and integrated with the custom ERP system, the solution lets the warehouse staff take a full control over the inventory in stock.

To forecast demand precisely, ML algorithms analyze extensive amounts of real-time information, historical sales data, market trends, consumer behavior, competitor activity, and external factors like seasons, weather conditions, and geopolitical events. This enables businesses to quickly respond to fluctuations in demand, ensuring effective resource allocation, optimizing warehouse and inventory management, streamlining transportation planning, and more.

It’s time for logistics companies to move beyond manual planning for transportation route optimization and fully embrace the power of AI. By evaluating variables like traffic patterns, fuel usage, and road and weather conditions, ML models for supply chain and logistics management help identify the optimal transportation routes and adjust them to changing conditions in real time. AI-powered route optimization significantly reduces not only shipping costs and delivery times but also the levels of fuel consumption and, thus, carbon emissions.

Self-driving vehicles are no longer sci-fi concepts from books and movies but powerful real-world tools that can revolutionize logistics. Powered by ML algorithms, self-driving trucks and cars can navigate the best possible transportation routes, respond to current traffic conditions, and avoid road hazards, delivering goods to delivery hubs and consumers much faster. AI-enabled autonomous drones can easily make last-mile deliveries to difficult-to-reach areas, such as densely populated regions, zones with congested traffic, and locations where ground transportation is impossible. Mordor Intelligence predicts that the drone delivery market will grow from $690 billion in 2024 to $1.75 trillion in 2029, with a CAGR of 20.33% over the forecast period. Although still in the nascent stage, autonomous vehicle technology is already revolutionizing the logistics sector, making the delivery process more efficient and accessible to all.

The synergy of ML, CV, robotics, and Internet of Things (IoT) devices and sensors elevates warehouse automation to the next level. AI-powered robots can autonomously navigate warehouse premises to fulfill a wide range of tasks, including tracking inventory levels, transporting goods, sorting and picking packages, monitoring shipments in real time, and more. Logistics companies that integrate AI into various aspects of warehouse automation maximize space usage in their storage facilities, enhance the accuracy of warehouse processes, and increase operational efficiency and delivery speed.

The potential of AI in logistics extends to predictive maintenance and damage detection. By blending ML capabilities with predictive analytics, businesses can identify potential equipment breakdowns and enable prognostic maintenance before failures cause operational disruptions and financial losses. Additionally, logistics firms can use ML and CV to identify defects in goods during transportation and shipment, allowing for quick resolution and reducing the impact on customer satisfaction.

Logistics businesses can confidently respond to changing market conditions and fluctuations by personalizing their shipping costs with AI. ML algorithms and predictive analytics allow supply chain firms to easily adjust their prices in real time based on supply, demand, competitors’ rates, and even customer purchasing patterns. AI-driven dynamic pricing offers organizations virtually unlimited flexibility in optimizing their costs, giving them an edge over the competition and increasing sales and revenue.

Chatbots, powered by NLP and generative AI (GenAI), can redefine customer service across numerous industries, including logistics and supply chain management. By using these smart tools, logistics companies can provide consistent and round-the-clock support for a variety of tasks, including changing order details, tracking shipments, requesting deliveries, and answering frequently asked questions (FAQs). AI-powered chatbots significantly elevate the quality of customer service, delivering hyper-personalized experiences and increasing customer engagement.

AI logistics use cases include intelligent document processing (IDP), which involves using optical character recognition (OCR) and NLP technologies to automate and enhance the extraction, interpretation, and processing of information from various logistics documents, such as bills of lading, purchase orders, freight invoices, and more. Logistics companies use IDP to streamline document management, reduce human error, and enhance the speed and efficiency of logistics processes.

Why use AI in transportation and logistics? This is probably the most common question asked by supply chain companies. In the next section, we outline the most significant advantages of incorporating AI in logistics.

Provides data-driven insights that guide proactive and accurate decisions, enhancing strategic planning and improving logistics outcomes.

Enhances efficiency by automating and streamlining inventory and warehouse management, customer service, document processing, and other critical aspects of the industry.

Minimizes reliance on human assistance, resulting in fewer mistakes and improving the accuracy and precision of logistics processes.

Lowers operational costs by reducing downtime and fuel consumption, preventing logistics disruptions, and enabling timely equipment maintenance.

Improves visibility into various aspects of the supply chain, including real-time tracking of current inventory levels, shipments, transportation routes, and more.

Boosts customer satisfaction by delivering hyper-personalized customer service, anticipating customer demand, and reducing delays and delivery times.

Drives environmental sustainability by optimizing fuel and energy consumption, minimizing waste, carbon footprints, and air pollution.

The role of artificial intelligence in logistics is becoming more pronounced. However, integrating AI into industry processes is fraught with challenges. Here’s a breakdown of some potential obstacles and how to overcome them.

| Challenge | Solution |

|---|---|

| Considerable implementation costs | – Implement AI capabilities in several phases. – Leverage cloud-based platforms that offer a pay-as-you-go pricing model to reduce costs. |

| Lack of specialized talent | – Organize necessary training for employee reskilling or upskilling. – Invest in external expertise. |

| Privacy, security, and ethical concerns | – Curate your data. – Implement data protection measures: encryption, access control, data masking, etc. – Conduct security audits and training. – Develop incident response plans. – Ensure compliance with industry-specific regulations, such as GDPR. |

| Integration with existing or legacy systems | – Tap into incremental integration with pilot projects and make adjustments based on real-world results. – Try various integration approaches, such as using middleware or APIs, to facilitate communication between existing or legacy systems and AI tools. – Use cloud computing to integrate AI and eliminate the need to upgrade on-premises infrastructure. |

| Resistance to change | – Explain the value and benefits of AI to company stakeholders. – Provide comprehensive training and ongoing support. – Establish clear success metrics. – Foster innovation and continuous improvement. |

Logistics businesses willing to stay ahead of the curve have already made AI part of their digital transformation strategy. Next, we outline several prominent AI in logistics examples among industry leaders.

Amazon is an e-commerce giant that delivers goods to customers worldwide through its Amazon Logistics service. The company has implemented AI technology to streamline its logistics operations across the supply chain, accelerate the delivery process, and drive customer satisfaction. Amazon uses AI to accurately predict customer demand; uncover damaged products using Project P.I. (Private Investigator), its proprietary AI model; and optimize warehouse and inventory management through AI-powered robotic systems, such as Sequoia and Digit. Currently, over 750,000 robots operate in Amazon’s fulfillment centers, tackling time-consuming and repetitive tasks. Its other proprietary AI model, the Package Decision Engine (PDE), enables the organization to use the most efficient and sustainable packaging for customer orders, significantly reducing package waste in the eco-friendly era.

FedEx’s numerous AI initiatives over the past few years have solidified its reputation as an AI logistics company. By using AI to analyze weather and traffic conditions, FedEx provides precise delivery time estimates, improving delivery experiences and increasing customer satisfaction. Additionally, FedEx capitalizes on ML capabilities to forecast customer demand and the volume of packages to be delivered daily, provide personalized customer support, and drive smart logistics. In collaboration with Dorabot, the company has introduced an AI-powered sorting robot, DoraSorter, that arranges inbound and outbound parcels based on their destination, increasing operational efficiency and decreasing labor costs. The FedEx Sustainability Insights platform is another example of how the firm has employed ML algorithms to help companies evaluate and manage their carbon footprints, eventually reducing their environmental impacts.

DHL, a global leader in the logistics industry, is neck-and-neck with the competition when it comes to implementing AI technology. The organization has revolutionized its warehouse and distribution operations by deploying AI-powered Locus Autonomous Mobile Robots (AMRs) that help employees automate and optimize picking and order fulfillment tasks. By implementing over 3,000 Locus AMRs in its global facilities, DHL has dramatically improved productivity and accuracy, reduced physical strain for employees, and cut labor expenses. To decrease the usage of outer cardboard packaging by 50%, thereby minimizing carbon emissions, the company has developed AI-powered software, OptiCarton, that can determine the ideal shipment overpack based on product characteristics, volume, and dimensions. In addition to AI-enabled robots and the OptiCarton solution, DHL leverages ML models and predictive analytics to optimize transportation routes, gain end-to-end visibility into its supply chains, and provide seamless customer service 24/7.

Maersk is an undisputed leader in maritime logistics that manages a wide variety of operations on a daily basis, including warehousing, shipping, transportation, distribution, and more. Driven by the idea of “zero touch logistics,” which minimizes human intervention in logistics processes, the conglomerate has embraced a broad spectrum of next-gen advancements, including AI. To optimize warehouse and inventory management processes, Maersk has implemented AI-powered Robotic Shuttle Put Wall (RSPW) systems. These solutions excel in sorting customer orders, picking batch inventory, and managing order profiles and packages, accelerating operational speed and efficiency threefold. Additionally, Maersk uses AI tools to handle contract negotiations, provide real-time visibility and traceability for supply chain operations, increase customer service quality, improve transportation routes, and more.

If your business aims to achieve significant logistics outcomes, incorporating AI into relevant operations isn’t a luxury anymore—it’s a necessity. Below, we highlight the recommended steps to seamlessly integrate AI into your logistics and supply chain processes.

Orchestrating various logistics workflows and operations is a complex and time-intensive process that exerts a significant impact on the success of the entire supply chain. In a world where next-gen AI technology is the need of the hour, many logistics businesses still dismiss it as a marketing gimmick, which, of course, is fraught with the risks of stagnation and potential business failure. Are you a supply chain company that strives to succeed and prosper just like the AI in logistics examples in this article? Partner with our AI-savvy company today and enter the world of transparent, reliable, and cost-efficient logistics tomorrow.

Businesses harness the power of AI to optimize logistics with applications, such as demand forecasting, smart route optimization, predictive maintenance and damage detection, and many others.

EffectiveSoft helps logistics businesses of all sizes implement AI technology to create smart warehouses and intelligent inventory management systems, provide excellent customer service, enable dynamic pricing, and more.

The costs of implementing AI into logistics and transportation can vary significantly and typically include investment in underlying infrastructure, maintenance and support, employee training, and more. A wide range of factors, such as specific needs, the project’s scope, and the complexity of logistics operations, can influence the final cost of AI integration into transportation and logistics. Do you want our specialists to estimate the price for your AI project? Contact us now!

Yes, small and medium-sized logistics businesses can benefit significantly from AI. They can use the technology to streamline relevant processes, increase delivery speed, drive considerable cost savings, boost customer satisfaction, and more.

The future of AI in logistics is promising. AI technologies, such as ML, CV, and NLP, will continue to transform the vertical, making logistics operations even more intelligent, robust, and resilient.

Can’t find the answer you are looking for?

Contact us and we will get in touch with you shortly.

Our team would love to hear from you.

Fill out the form, and we’ve got you covered.

What happens next?

San Diego, California

4445 Eastgate Mall, Suite 200

92121, 1-800-288-9659

San Francisco, California

50 California St #1500

94111, 1-800-288-9659

Pittsburgh, Pennsylvania

One Oxford Centre, 500 Grant St Suite 2900

15219, 1-800-288-9659

Durham, North Carolina

RTP Meridian, 2530 Meridian Pkwy Suite 300

27713, 1-800-288-9659

San Jose, Costa Rica

C. 118B, Trejos Montealegre

10203, 1-800-288-9659